Business management support to every activity of the organisation which concerns with acquiring maximum prosperity with minimum efforts. Management plays significant role when group efforts are requires for achieve common goals (Fewings, 2013). It is dynamic function which includes labour, capital and raw-material to produce products. Present study is based on Toyota Motor Corporation which is Japanese company engage in design, manufacture, assembly and sale of passenger cars (Toyota, 2017). They are leading in auto manufacturer and take place eight largest company in the world.

In order to gain insight knowledge of company, report covers benefits of interrelationship between two functions within cited firm. Furthermore, it includes various activities to meet operational plan with effective monitoring and control. Moreover, it recommends to improvements within Toyota objectives and goals. In addition to this, it includes wider implications of proposed changes within Toyota company. At last, report carry out practical implications of health and safety policies and procedures within chosen organisation.

TASK 1

1.1 Evaluates the benefits of interrelationship between two functions of Toyota

Operation management defines as the administration of organisation practices which creates the highest level of efficiency possible within business. Main function of this aspect is converting material and labour into goods and services to maximize profits of Toyota.

You Share Your Assignment Ideas

We write it for you!

Most Affordable Assignment Service

Any Subject, Any Format, Any Deadline

Order Now View Samples

In order to take functions within the enterprise, teams compose organisation members from various level of the firm. Each function need to follow carefully which reduce cost and enhance good relations with customers (Wilton, 2016). For attaining goals of Toyota, following functions can be carry:

Marketing function:

Marketing functions is very essential part of business which need to get less attention from designer and information systems (Jansen, Cusumano and Brinkkemper, 2013). Productivity of marketing function of Toyota is depends on market forces and information system. With changing in market conditions effect to cited firm so that they have to conduct market research with changes in dynamic system. It gives information related with customer contact and other information such as budgetary control and infrastructure which assist to meet with marketing department.

Financial functions:

Finance is back bone of every enterprise which make support for effective functioning at workplace. Role of finance man change from last two decades (Too and Weaver, 2014). It involves activities which are related with preparation of financial report and performance enterprise. It is beneficial for Toyota because give information regarding investment, financial, assets management and portfolio aspects. Thus, it is very important responsibility of business to maintain accounting transactions at workplace which are related with business performances.

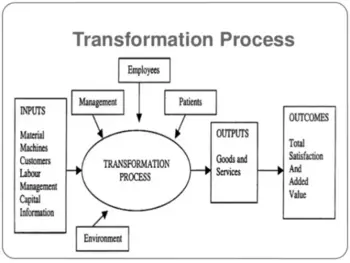

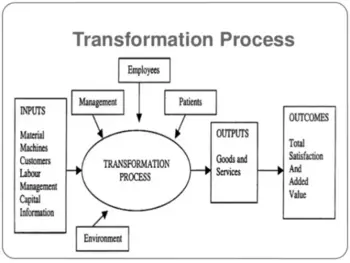

Transformation process includes activities and input in which Toyota add values to provide effective products to their customers. For instance, they are involves raw-material to make finished goods and take information regarding customers preferences (Obeidat and et.al., 2016). Then they are making products according to customers demand and serve to them.

With the help of this transformation process at Toyota, it facilitates real time decisions and improve automotive experiences. In inputs company use material, machines, customers, labour, management and many more things. These elements are gathering to achieve outcomes at workplace. It will give positive outputs in term of goods and services which satisfy customers demand and added value for maintain sustainability at workplace (Schmiedel Vom Brocke and Recker, 2014).

1.2 Suggest methodology which can be use in Toyota process to the organisation goals and objectives

In Toyota process, value stream mapping method can be use for analysing current state and future design for various series of event. It takes process from beginning through to the customers (Ates and et.al., 2013). In the cited firm it is also known as material and information flow mapping. This method is uses to create step by step guide which create current state value stream map. In this aspect, cited firm make efforts which is conducted by people who involve in this process. It represents flow of material from suppliers to customers within chosen organisation. Value stream mapping is team exercise which involve representatives from all areas within the process can be mapped (Somsuk and Laosirihongthong, 2014). In value stream method, company can employ flow diagram documenting with the high details of every step of a process.

Value stream mapping method is chosen because with the help of value stream mapping, chosen organisation can analyse and design flows in the system level. It is also relates with manufacturing which is uses in logistics, supply chain and service related industries. With the help of this method, activities of the enterprise can be make easily and separate which focus on one types of attention and another type of waste (Fewings, 2013).

1.3 Evaluate the purposes of quality gateway in Toyota's operations department

Quality gateway is an organisational point in which all requirements must pass. With the help of gateway specification is to trap incorrect requirements which preventing incorrect requirements which passing through design and implementation. In product development quality gateway play very important role which stand to reason for making correct design of products and services (Wilton, 2016). With the help of quality gateway, firm Toyota tests the requirements. In this aspect, requirement must pass through before it take part within specifications. Quality gateway normally set-up with one or two people at workplace.

Process mapping is defines as task which determine exactly which organisation does, responsibilities and standards which essential to take by Toyota. In process mapping cited firm seen single entity with taking interconnecting parts within the enterprise. Each part of interconnecting directly and indirectly adds value with end products and services (Jansen, Cusumano and Brinkkemper, 2013).

TASK 2

2.1 Operational Plan

Toyota UK is a company that operates with Total Quality management strategy. The operational plan which is devised on the theory of Management by objectives for this company is described below:

1.Review of organisational objectives:

Strategic working can only be guaranteed if certain goals and objectives are defined by organisation (Evans, 2016). Toyota's objective is to continuously improve quality of products for achieving customer satisfaction and demands.

2.Setting of employee objectives and targets:

Employee objectives help in increasing productivity of workers.They must have a motive of&valuable service deliverance. Moreover, additional rewards and incentives will enhance their quality of work (Wilson,2014).

3.Monitoring progress:

monitoring is essential in an operational plan. Complete transformational changes of raw materials take place in operations department of the company. From manufacturing, finance and sales to marketing, promoting and delivering products to consumers, every activity has to be monitored for errorless functioning.

4.Evaluation of performance:

performance of employees and functioning department has to be evaluated so that conclusions can be made whether objectives are being accomplished or not.

5.Distributing rewards for achievements:

Declared rewards and incentives must be distributed to deserving candidates so that their spirit is motivated and inspired for more work (Meistering and Stadtler, 2015).

6.Planning MBO for next operational period:

As soon as the current operational plan is executed and evaluated, next plan is prepared for another operational period.

2.2 SMART objectives

SMART is a combination of specific, measurable, achievable, realistic and time based objectives which are defined for a company so that it can innovatively progress and expand in international and national markets (Oakland, 2014). SMART objectives for Toyota are designed ahead:

- To achieve a sustainable business platform by managing triple bottom line standards.

- To manage its operational base in such a way that customers gain maximum awareness about company's products and services with achieving cost effectiveness.

- To prosper and conquer international markets by creating employment opportunities in countries that have high levels of unemployment.

Above described objectives qualify smart criteria and also help in creating a better brand image of the company. Operational plan must be based on SMART objectives as it helps in connecting with employees in a humane way (Hunter, and Nielsen, 2013). Moreover, main motive of the company to serve its clients and their expectations effectively is also fulfilled with these objectives.

2.3 Implement appropriate system to achieve objectives in the efficient way

In order to achieve organisation objectives, Toyota can be use following methods:

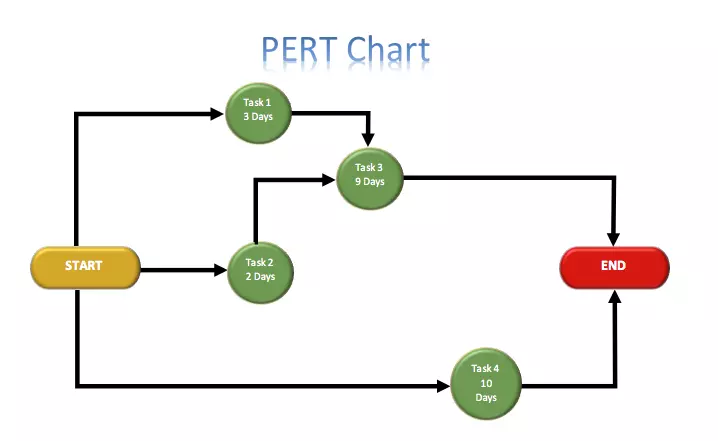

Programme evaluation and review techniques (PERT):

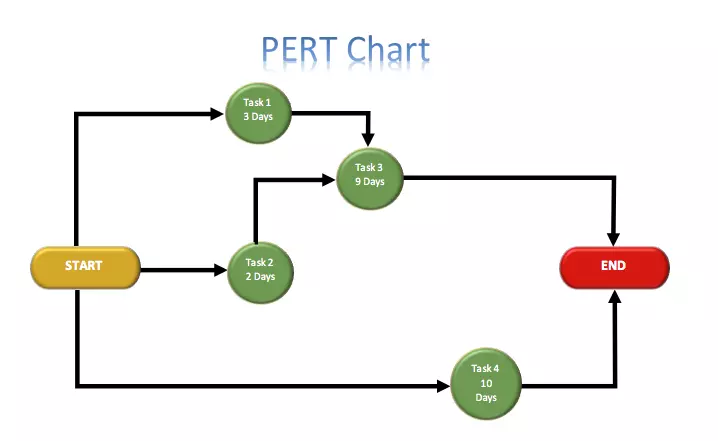

PERT is method which uses to schedule, organize and coordinate tasks within event of firm. It represents graphical of each activity within cited firm. This tool emphasize to make relationship between each task and activity which complete within specific time frame. This system are design to manage complexity at workplace which is major components of extensive data and industrial efforts (Too and Weaver, 2014). Major effectiveness of this tool is that it allows flexible scheduling due to variations in the amount of time takes to accomplish specific part of project. In addition to this, activity is defines according to time frame and resources which are requires moving from one event to another. When one event is completed, progress and performance of company can be monitors easily.

Critical path analysis (CPA):

Various business involve in major projects that are complex and includes significant investment and risk. Complexity and risks increasing which is very necessary for identify relationship between each activity of project (Obeidat and et.al., 2016). It is very essential to use CPA for construct model which includes all activities related with Toyota, time for accomplish each activity and dependence between each activity. Effectiveness of CPA is that company can plan all task which must be completing as a part of project.

2.4 Recognise project planning model and tool

In order to make plan within Toyota, project management develops and coordinate diverse activities of modern industry and commercial projects. Aim of manager through project management is foreseen and predict problems which they may face at workplace (Schmiedel Vom Brocke and Recker, 2014). Thus, they have to make plan to solve this issues which organise and control activities so that project can be complete successfully. Manage of the chosen organisation can involve various activities such as deciding what things to be done, organising it and making arrangement with taking right candidates at workplace. Their aim which need to be accomplish are performance and quality, budget and time to completion (Ates and et.al., 2013).

With taking PERT manager can easily implement their plan to accomplish Toyota objectives. In this aspect, they can assess and monitor business outcomes to maintain organisation growth. In cited firm, PERT analysis provide visual depiction which includes major project activities and sequence for accomplish desires outcomes. Network diagram consist arrows and nodes which need to be organize for accomplish activities within the enterprise. Sequence activities leading from starting point of diagram and finishing point of the diagram which is known as path (Somsuk and Laosirihongthong, 2014). In this method, manager can involve various activities to compromising different degree of certainty.

TASK 3

3.1 Select two quality system which are applied on Toyota

Quality is the standards which can be measure against things which are similar kinds of other products and services. In quality standards are meet with excellence performance of Toyota which are achieves in term of uniformity of products and services. In order to meet with quality standards, organisation measure various quality aspect within the enterprise (Fewings, 2013). It is the process which includes collection of business process which focuses on consistency to meet customers requirements and enhance their satisfaction with business activity.

In Toyota ISO 9000 is taken for quality measurement which determines international standards on quality management and quality assurance within the enterprise. It assists to cited firm to develop quality system element which need to implement to maintain efficient quality at workplace. It is not necessary for any organisation which can be applies on firm size (Jansen, Cusumano and Brinkkemper, 2013). In addition to this, cited firm also adopt EN 29000 quality standards' consultant which make witnesses within the company to recommends carefully regarding business operations and their products. With the help of these standards, Toyota can easily analysis their performances towards customers outcomes. They can measure quality of their products and services which they offer to users and clients.

3.2 Total quality management

Total quality management is based on principles which requires for every member of staff to commit with work and maintains high standards of work. It is a system of management which describes continual improvements in Toyota products and services at workplace (Too and Weaver, 2014). It uses strategy and data with effective communication to integrate quality discipline with culture and activities. It is based on various elements such as customers focuses, employee involvement, integrates system and fact based decision-making, etc. When organisation focuses on their customers, they can ultimate determines level of quality with improvements in employee training, integrating quality and design process (Obeidat and et.al., 2016). It creates quality culture with integrates process centred in which company have to focus on common goals which need to be accomplish in series of steps which take place from suppliers and end with customers.

You Share Your Assignment Ideas

We write it for you!

Most Affordable Assignment Service

Any Subject, Any Format, Any Deadline

Order Now View Samples

In addition to this, it is also measures communication for day to day operations of Toyota company. Effective communication play vital role which maintain morality of employees at all level of the enterprise. Quality culture is a set of group values which need to take guidance for everyday working practices and consequent outputs (Somsuk and Laosirihongthong, 2014). In cited firm TQM assist to make quality culture due to taken granted practices which encapsulate the ideology of group of firm. When cited firm find that their customers are unhappy, they have to adopt new technology to frame culture and monitor organisation performances.

3.3 Recommend improvements which align to achieve business objectives

In order to achieve business objectives, Toyota need to make changes in their plan with the help of business process re engineering. It involves design of core business process to achieve improvements in cited firm productivity, cycle time and their products quality. Business process re engineering is the analysis between workflows and activities of the organisation to optimize core value within company (Fewings, 2013). With the help of business process following recommendations can be taken within cited firm:

- Organize around outcomes not with tasks.

- Priorities every activity of Toyota and redesign within the enterprise.

- Integrates information processing work with producing information at workplace.

- Capture information from market to optimize task at workplace.

- Put decisions point to perform various activities and build control on the process (Wilton, 2016).

3.4 Implication with proposed changes within Toyota

With the help of culture improvements, Toyota can implement their plan to make effective operations within the business. In respect to this, cited firm need to implement plan for maintain quality at workplace. The organisation need to make systematic transactions and activities which can be done through maintain quality at workplace. It gives positive results, on the enterprise performances in term of pressures managers and new approach of quality (Too and Weaver, 2014). Total quality management is tool which based on research that explore new things at workplace. As results, cited firm can move towards multinational things which they can implement in business. They are defines true culture of quality as an environment in which employees need to follow guidelines and consistency which are based on quality, focus actions and quality all around the enterprise.

TASK 4

4.1 Risk assessment process

It is vital that risk assessment process should be carried out for identifying potential damages and harms that can occur in the Westfield London shopping centre. It will support in making effective strategies for mitigating the negative impact of risk that might be faced in the enterprise (Hughes, and Ferrett, 2015). Risk assessment will be conducted by following way :-

Organisation name:

Westfield London shopping centre

| What are the hazards? |

Who might be harmed and how? |

What are you already doing? |

Do you need to do anything else to manage this risk? |

Action by whom? |

Action by when? |

Done |

| Slips and trips |

Employees might get injured if they will fall or slip due to any object. |

Staff members are informed about the various risk that might be faced by them due to the various risk |

Effective management of equipments is required and it will support for avoiding slips |

All employees,supervisor to |

04/10/16 |

05/10/16 |

| What are the hazards |

Who might be harmed and how |

What are you already doing |

Do you need to anything else to manage the risk |

Action by whom |

Action by when |

Done |

| Â |

|

conditions |

and trips in the entity |

monitor |

|

|

| Health related risk |

staff members and consumers visiting the place might get injured due to the serious damages might be suffered. |

Precautions needs to be taken by people while visiting shopping centre has been posted on the notice board (Mitroff and Alpaslan, 2014). |

staff members are provided with training programs so that they can learn better ways for providing better services to consumers. |

staff members, top management and customers |

6/ 12-2016 |

7-12-2016 |

4.2 Application of health and safety regulations on work environment

Three legislative measures that applied to Westfield London shopping centre are as described :-

Health and safety act 1974 :-

Guidelines have been mentioned in this act that it is necessary to maintain safe operations and managing of working environment. It is required that adequate welfare provisions should be provided to staff members and proper training should be provided to them for ensuring better health and safety at shopping centre (Flannigan, Samson,and Miller,2016).

Workplace regulations 1992 :-

According to this act it is required that proper maintenance of the work place equipments should be done and conductive work environment should be provided to staff members.

The health and safety regulations :-

Guidelines have been mentioned in the act that employers are required to provide health and safety regulations to the workers (Wuttke, Blome and Henke, 2013).

4.3 Health and safety procedures adopted in the organization

Health and safety policies are followed in Westfield London shopping centre for rendering safe and protective work environment to clients.

7.Risk assessment processes are organized for identifying potential sources of risk that might be faced in the enterprise (Frumkin, 2016).

8.Training sessions are organized for making staff members aware about the various health and safety related issues that might be faced by them while working.

9. In addition to that consumers are given information about various health and safety related issues by posting notice and distributing pamphlets.

10.Risk in the organizations are managed by forming effective risk policies.

4.4 Practical implications of health and safety policies and procedures

Westfield London shopping centre is visited by millions of people and it is needed that better and safe environment should be rendered to all the staff members. Training programs can be organized in enterprise for making people aware about the various health and safety policies that they need to follow (Wilks, JStephen and Moore, 2013). In addition to that monitoring of safety improvement will be done by making a check list and it will aid in identifying weak performing areas of safety and health in the corporation.

Conclusion

From the above report it can be concluded that, Toyota need to manage their business activities for achieve business objectives at workplace. In this aspect, they are follows functions which re interrelated with each other such as marketing and financial function. Furthermore, it summarized that for developing operational plan cited firm need to apply SMART objectives for effective and efficient use of resources. Moreover, it articulated that for maintain quality system cited firm need to use total quality management with the help of PERT and CPA.

References

- Ates, A. and et.al., 2013. The development of SME managerial practice for effective performance management. Journal of Small Business and Enterprise Development. 20(1). pp.28-54.

- Evans, M., 2016. GLIS 620-Management of Information Organization-Week 2-Strategic Planning, Goals and Objectives. 1. pp.

- Fewings, P., 2013. Construction project management: An integrated approach. Routledge.

- Flannigan, B., Samson, R.A. and Miller, J.D., 2016. Microorganisms in home and indoor work environments: diversity, health impacts, investigation and control. CRC Press.

- Frumkin, H. ed., 2016. Environmental health: from global to local. John Wiley & Sons.Hughes, P. and Ferrett, E., 2015. Introduction to Health and Safety at Work: For the NEBOSH National General Certificate in Occupational Health and Safety. Routledge.

Amazing Discount

UPTO55% OFF

Subscribe now for More

Exciting Offers + Freebies